Feed hygiene

Maintaining safe feed is essential for producing safe food. Animal feed is always at risk of being contaminated with spoilage and pathogenic microbes such as Salmonella, E. coli, mould and yeasts, which can affect the nutritional quality of feed and lead to reduced animal performance. Some microbes, such as Salmonella, can even pose a public health hazard.

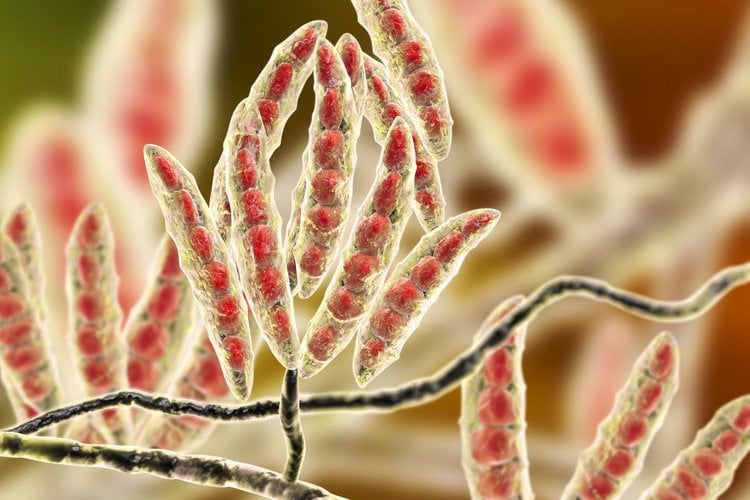

Mycotoxin Risk Management

Contamination of raw materials with mycotoxins in the field or during storage at feed mills is a significant challenge in maintaining the quality of final feed. Failure to achieve high quality of feed can mean economic losses for feed millers as a result of poor feed prices, diminished brand image and compromised performance of animals.

Process Moisture Management

Process moisture loss, also known as ‘shrinkage’ is an inevitable part of feed processing. Ineffective management of process moisture can cause serious problems in the quality of the final feeds. Possible issues include reduced shelf-life, inconsistent nutritional value and increased levels of dust by broken pellets, all of which can impact animal performance and your brand’s image. However, effective process moisture management can deliver significant economic savings for feed millers.

Enhancing feed stability

When manufacturing feed, three components are key - nutrient stability, physical quality and additive stability. These are essential for adding value to your feed and helping differentiate your product in the marketplace. It’s important to understand how ingredients react and interact with each other, potentially reducing the overall stability and bioavailability of their nutrients.